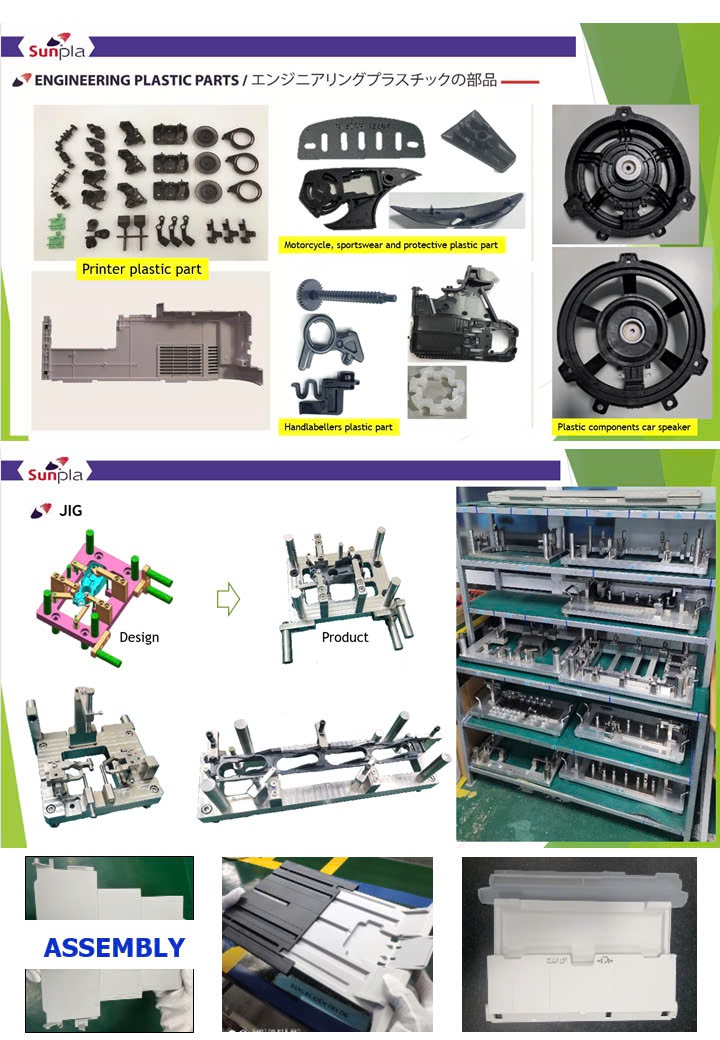

We have variety of machine and equipment. Together with a professional designer team and strong support from our customers. We are proud to have been made hundreds of quality products for our customers.

All of our injection molding machines are Japanese technology with high performance of quality and accuracy. We believe that we will make the best products following the requirement of customers.

We deeply understand your concern about measurement accuracy. Base on part’s drawing and functional, we will design and make Jig to measure part dimension.

To optimize production efficiency and reduce the loss related to transportation, we can carry out the extra process such as printing or assemble semi-finished products from the products that we make.

We have experience in tampon printing and silk printing. By this way, we can add more values for our products and services.

.

.

.

With the spirit of always learning to improve operation systems and with more than 10 years of experience in the fields of mold design & manufacture, plastic injection molding. We provide all services related to the field of molds and injection plastic components production such as design, manufacturing, repair, production, assembly, printing…

Your feedback empowers us!

We have about 40 processing machines with diverse types of machines. Such as Fanuc Robodrill, Vertical Matching Center, Wire cut, EDM, CNC milling, hobbing machine, surface grinders, …

Please refer here to get more details.

(Updated base on 2024 situation. The actual performance can be better in next years)

We classify according to mold/die size

2024 target: 300 sets

(Updated base on 2024 situation. The actual performance can be higher in next years)

We have 2 factory. The available IMMs / Maximum scales as below

All of our IMMs was make by Japanese technology (Sumitomo, JSW, Shibaura/Toshiba)

(Updated base on 2024 situation. We are still planning to continue investing in increasing the numbers of IMM to increase production capacity)

In 2024 we still have only horizontal injection molding machines with single injection screw

We have quite a full range of measuring tools for test and control part quality in the our field of manufacturing

The simple tools (small tools such as caliper, PG, BG) we can be calibration by our members who have calibration experience and certification

Other tools will be use a service from a third party (Job Full)

Beside the ISO certification, our quality system have been reviewed and audited annually by our customers, and we applied IT software to control warehouse (inventory, In-Out, FIFO), control quality trends, mold/ die/ machines/ equipment information.

There are the application that we are using